Inquiry

Form loading...

Driving scrubber efficiency and performance is crucial in various industries. Scrubber machines are often the backbone of cleaning operations. Enhancing their effectiveness can lead to significant cost savings and improved cleanliness.

Various factors influence the performance of a scrubber. Regular maintenance is essential but can be overlooked. This habit may lead to machines underperforming when needed most. Operators should be trained effectively to recognize signs of wear and tear. Understanding scrubber functionality can prevent costly downtime.

Moreover, the choice of cleaning solutions plays a vital role. Not all products are compatible with every machine. Improper selection can impair performance and damage equipment. It's important to test solutions for best results. Driving scrubber efficiency requires continuous evaluation and adjustment. Keeping an open mind about current practices can also lead to valuable discoveries. Unraveling these layers can ultimately optimize your operations.

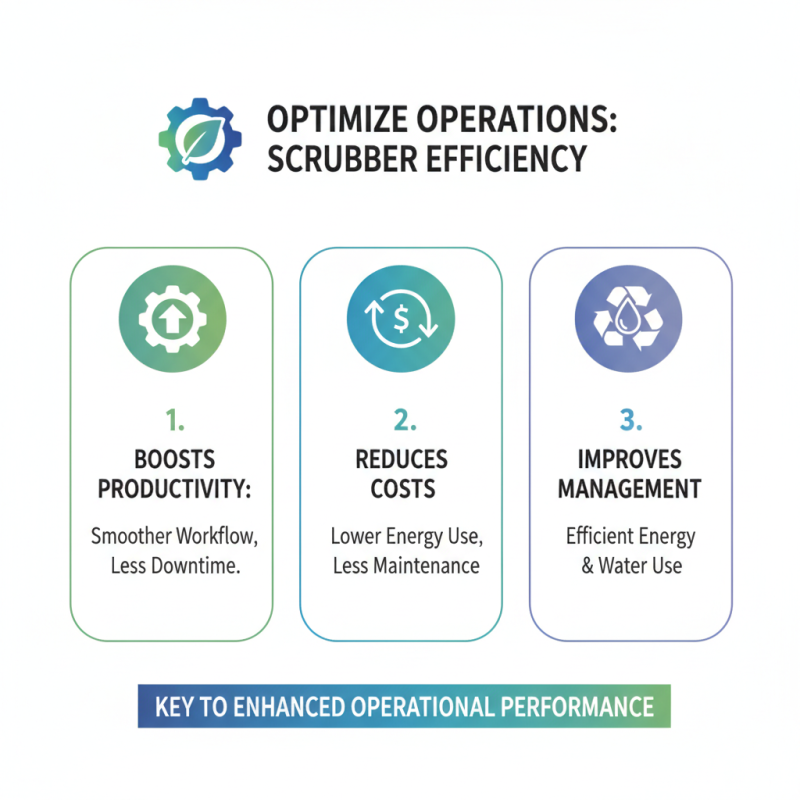

Understanding scrubber efficiency is crucial in enhancing operational performance. It directly impacts productivity and resource management. When scrubbers operate efficiently, they reduce energy consumption and maintenance costs. This creates a smoother workflow.

One tip for improving scrubber efficiency is regular maintenance. Check filters and components frequently. Neglecting these aspects can lead to clogs, inefficiencies, and costly repairs. Another important factor is to monitor the operating conditions closely. Minor adjustments can make a significant difference in performance. Don't overlook the impact of training staff. Well-trained operators will recognize issues quickly and maintain optimal performance.

Efficiency objectives should be realistic. Striving for perfection can lead to frustration. Instead, focus on incremental improvements. This approach often yields better long-term results. By understanding these factors, operations can achieve enhanced scrubber performance.

In industrial settings, scrubber performance is critical. Several key factors determine efficiency. First, the design of the scrubber plays a significant role. Proper dimensions and materials can enhance gas flow and minimize pressure drop. Research shows that a well-designed scrubber can improve removal efficiency by up to 30%.

Water and chemical usage also impact performance. Many facilities overlook the quality of water used. Poor quality can lead to scaling and reduced efficiency. Operating temperature can affect scrubbing reactions. For instance, a temperature increase can enhance reaction rates but may also raise energy costs. Balancing these aspects is challenging.

Routine maintenance is often neglected. This can result in reduced functionality over time, affecting output. Reports indicate that up to 20% of scrubbers fail to operate at peak efficiency due to lack of servicing. Operators should regularly check for wear, leaks, or blockages. They must remain vigilant about these factors to ensure optimal operation. Adjustments might be needed as operational conditions change, reflecting the need for continuous improvement.

Regular maintenance is key for enhancing scrubber longevity. Routine checks prevent minor issues from escalating into major problems. Inspecting filters, hoses, and seals is essential. A worn-out hose can lead to decreased performance. Regularly cleaning components keeps the scrubber running smoothly. It reduces wear and tear, extending the lifespan of the machine.

Don’t ignore the simple tasks. Replacing worn brushes might seem trivial, but it can greatly impact efficiency. Also, monitor fluid levels frequently. Low fluid levels can cause overheating. Striking a balance between maintenance and usage is crucial. Overusing a scrubber without proper checks leads to inefficiency and costly repairs. Take a few moments each day to evaluate the scrubber's condition. It pays off in the long run.

This chart illustrates the impact of various maintenance practices on the efficiency of scrubbers. Regular maintenance is shown to have the highest impact, ensuring optimal performance and longevity of equipment.

To maximize scrubber efficiency, creating optimal operating conditions is crucial. Scrubber systems function best when they are well-tuned to their environment. According to a recent environmental report, maintaining a flue gas temperature below 150°C can significantly enhance absorption rates. Monitoring humidity levels is equally important. Studies show that ideal humidity should be between 70% and 90% for maximum effectiveness. Any variance can lead to reduced performance.

Chemical concentrations play a significant role as well. The right mixture can improve scrubbing efficiency by over 15%. However, achieving this balance is challenging. Too high or too low a concentration may decrease the system's ability to capture pollutants effectively. Additionally, regular maintenance is necessary but often overlooked. Keeping nozzles clean can lead to a 20% increase in operational efficiency.

Many operators often underestimate the impact of these factors. For instance, operating under unsteady conditions might result in fluctuating performance levels. This inconsistency calls for constant reevaluation. Regular data analysis can uncover underlying issues, but implementation can be sporadic at best. Each aspect of scrubber management requires attention to detail and commitment to improvement for truly effective results.

Monitoring scrubber performance metrics is crucial for improving efficiency. Regular analysis helps identify strengths and weaknesses in the system. Data shows that optimizing throughput can lead to a 20% increase in operational efficiency. Utilizing dashboard tools for real-time performance tracking can enhance decision-making processes.

Implementing scheduled inspections can help maintain scrubber effectiveness. Aim for at least bi-weekly checks. Visual inspections can catch issues before they escalate. Consider using vibration analysis, which is shown to reduce maintenance costs by up to 15%.

Performance can also be enhanced by understanding key metrics such as pressure drop and flow rate. These indicators provide insight into potential areas of improvement. Remember, not all scrubbers perform equally under the same conditions. Testing different operational parameters can reveal valuable data to refine usage strategies.